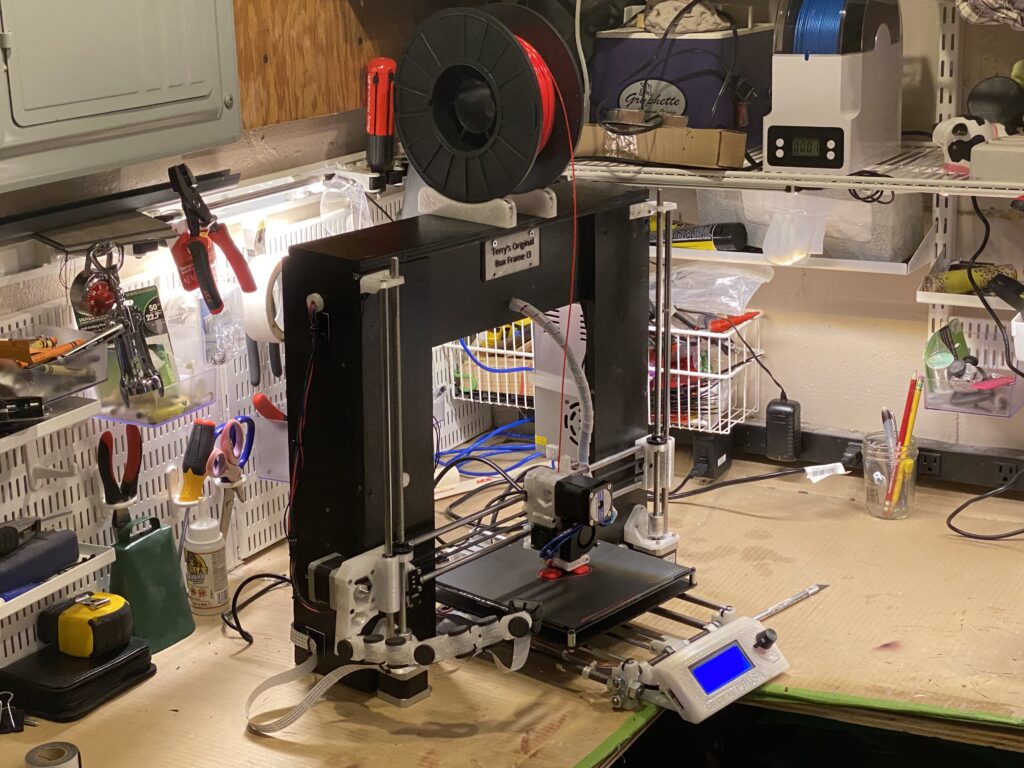

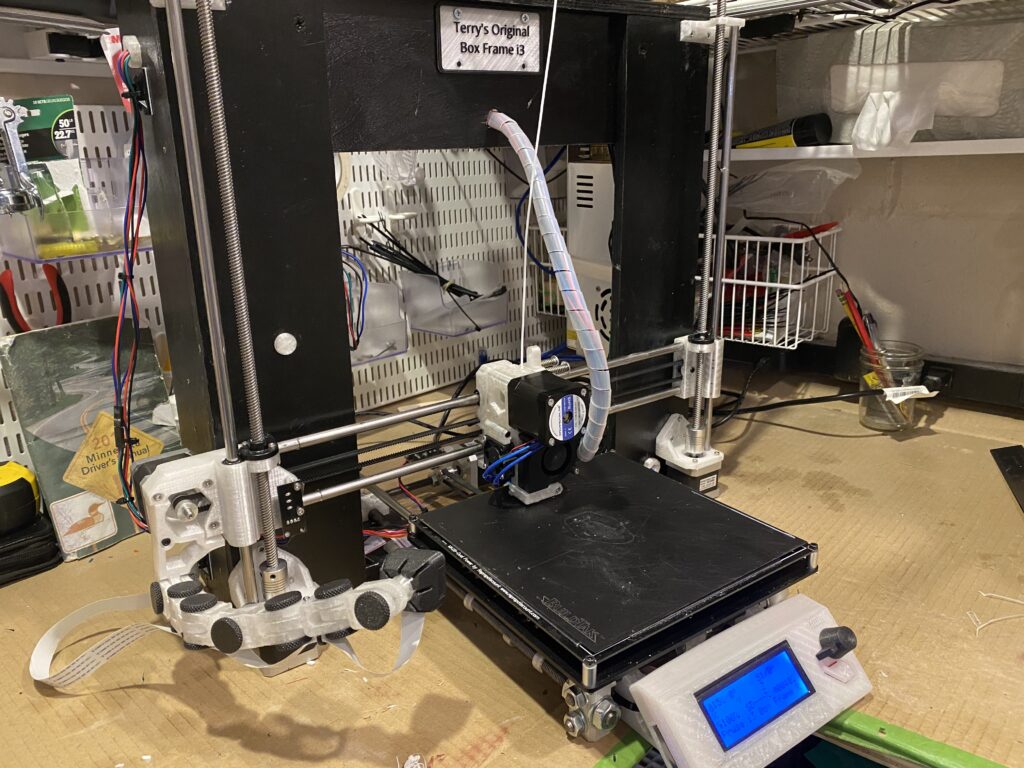

Above photo is of a rebuild of the Boxframe printer, essentially a Prusa MK3 Hybrid that I built in 2019. Officially, newer Prusa designs all used machined plates for the frame and no one builds box frame printers these days. However, since I had the boxframe but wanted to retire the Prusa i3, I decided to salvage the box frame and create a hybrid design that used more modern printed parts. I used the relatively recently designed open source Prusa MK3 parts and modify them to work with box frame and also use a few of the original i3 parts like the stepper motors, belts, pulleys, printbed, etc. allowing me to essentially build a boxframe version of the MK3 on the cheap. All of the parts were printed on the Prusa MK3s kit in PETG. The end result is a 3d printer that was able to print close to the same print quality and reliability as my kit version of the MK3s.

I also used this as a platform to experiment with the klipper 3d printer firmware and software that uses software running on a raspberry pi to tune the printer and achieve higher print speeds.

This printer now lives at our lake place in Central MN and was used to print all of the parts for the tripod I designed for the OpenAstroTracker and often gets used to make replacement parts, miscellaneous shop projects and household items.

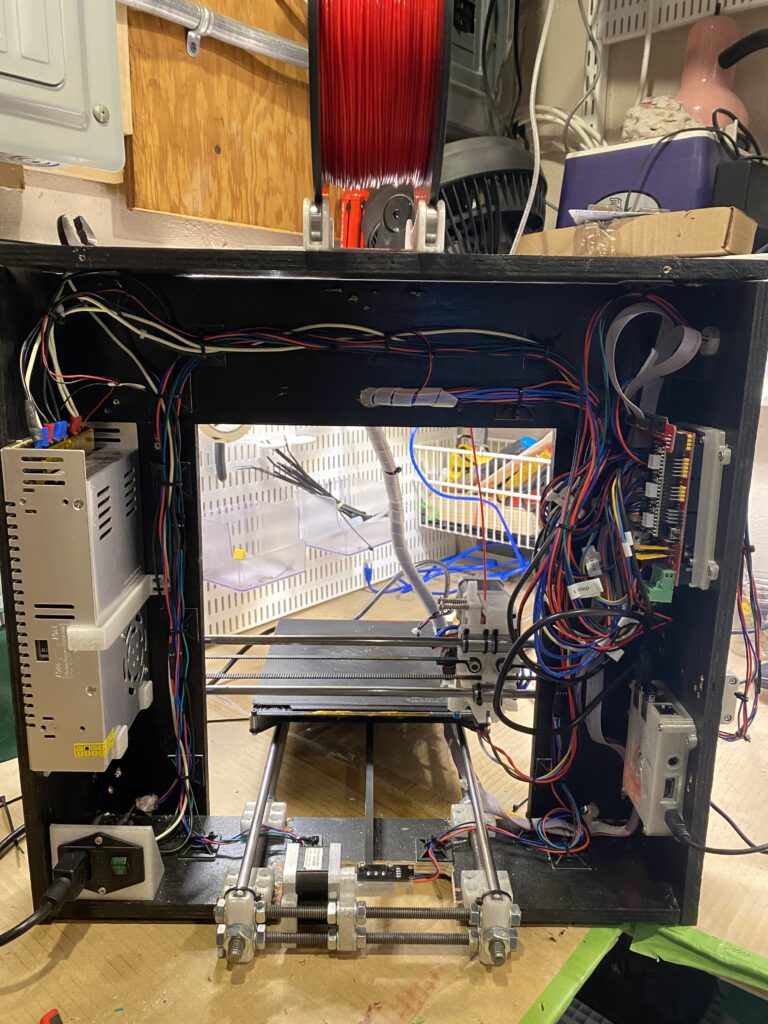

Inside the Box

Power supply is mounted on the left side (from the back), controller board and raspberry pi are on the right.

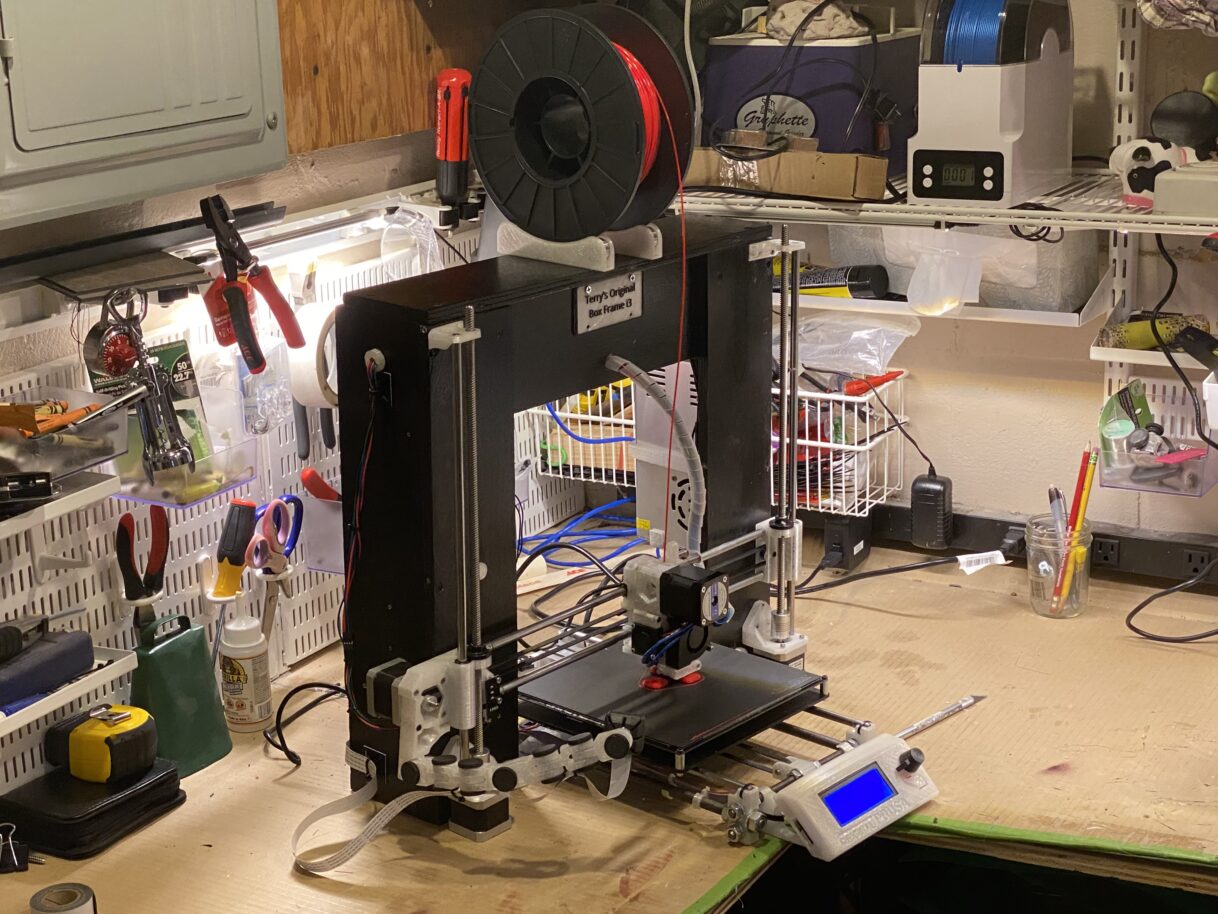

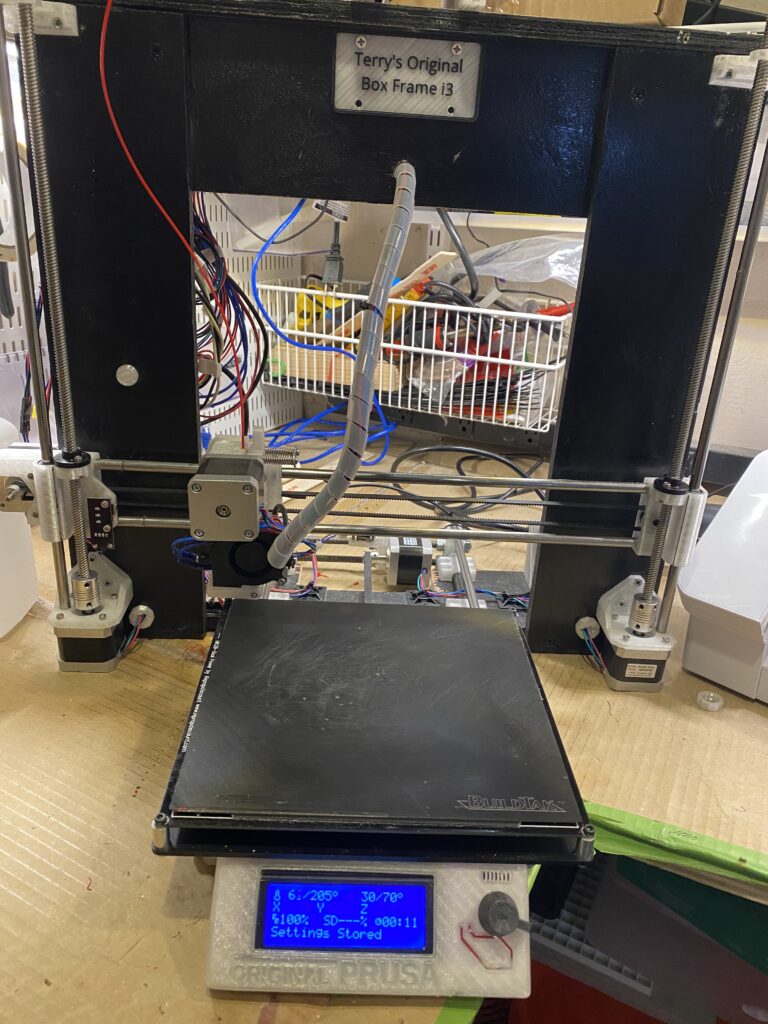

From the front:

I had acquired a LCD display from a junky cheap delta printer that I bought at a garage sale and was able to use it here. It was also the source of a few additional upgrade parts. In the picture at the right you can also the raspberry pi camera that I added.

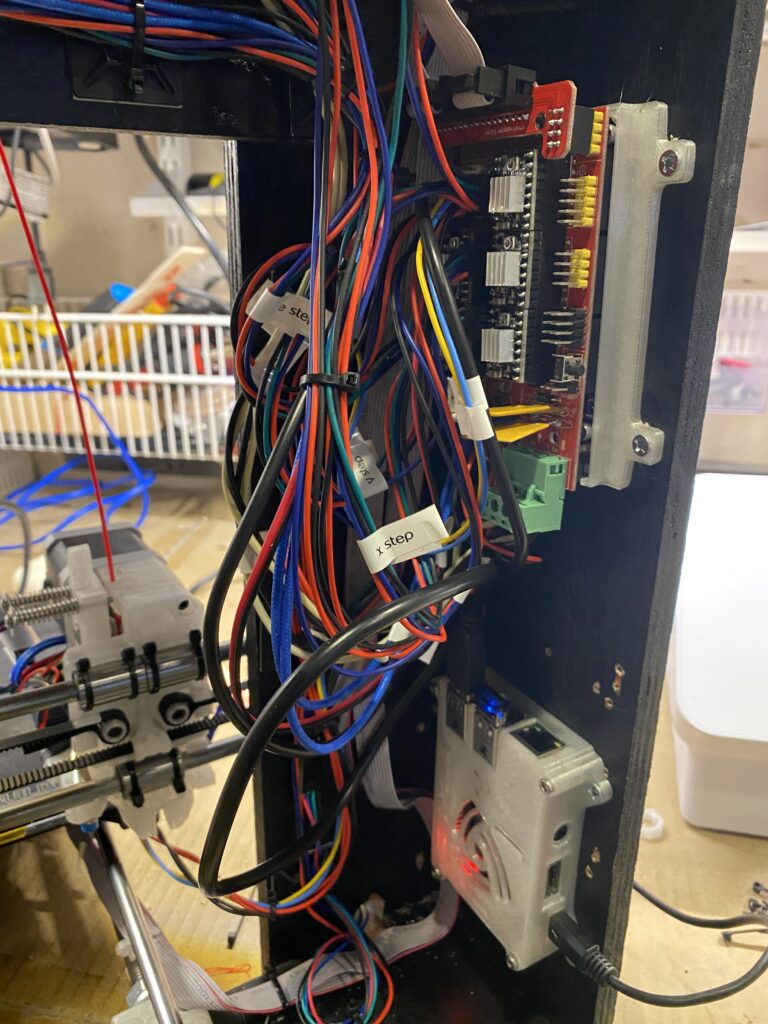

The Extruder:

The extruder is a “modern” direct drive extruder.

One last full frame shot: